English

English Esperanto

Esperanto  Afrikaans

Afrikaans  Galego

Galego  беларускі

беларускі  Shqiptar

Shqiptar  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  Кыргыз тили

Кыргыз тили  Монгол хэл

Монгол хэл  IsiXhosa

IsiXhosa  Zulu

Zulu  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Հայերեն

Հայերեն  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Pilipino

Pilipino  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  नेपाली

नेपाली  Burmese

Burmese  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Azərbaycan

Azərbaycan  Lietuvos

Lietuvos  Română

Română  Srpski језик

Srpski језик

- Auto Radiator

- Toyota Auto Radiator

- Benz Auto Radiator

- BMW Auto Radiator

- Ford Auto Radiator

- Chevrolet Auto Radiator

- Honda Auto Radiator

- Tucson Auto Radiator

- Jaguar Auto Radiator

- Kia Auto Radiator

- Mazda Auto Radiator

- Nissan Auto Radiator

- Volkswagen Auto Radiator

- Mitsubishi Auto Radiator

- Fiat Auto Radiator

- Jeep Auto Radiator

- Dodge Auto Radiator

- Volvo Auto Radiator

- Lincoln Auto Radiator

- Infiniti Auto Radiator

- Audi Auto Radiator

- Suzuki Auto Radiator

- Opel Auto Radiator

- Electrec Auto Radiator

- Hyundai Auto Radiator

- Daihatsu Auto Radiator

- Subaru Auto Radiator

- Rover Auto Radiator

- Other Auto Radiator

- HEATER CORE

- Daewoo Auto Radiator

- Auto Condenser

- Audi Air Conditioning Condenser

- Ford Auto Condenser

- Benz Auto Condenser

- Jeep Auto Condenser

- Infiniti Auto Condenser

- Toyota Auto Condenser

- Honda Auto Condenser

- Nissan Auto Condenser

- BMW Auto Conderser

- Hyundai Auto Condenser

- Mitsubishi Auto Condenser

- Dodge Auto Condenser

- Rover Auto Condenser

- Jaguar Auto Condenser

- Fiat Auto Condenser

- VW Auto Condenser

- Auto Intercooler

- Transmission Radiator

- Evaporator Core

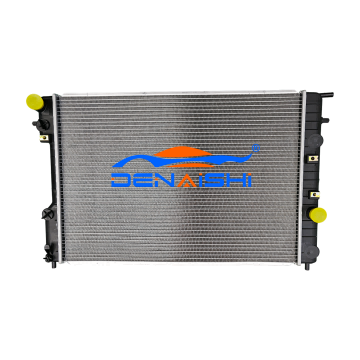

radiator for OPEL ASTRA G 2.2 TD 2172 Y22DTR 00- AT

Send Inquiry

DENAISHI® stands as a value-driven, service-oriented enterprise specializing in the integration and supply of automotive heat exchange systems, seamlessly integrating product development, precision production, efficient sales, and comprehensive after-sales service into a cohesive operational model. Since its establishment, the company has been committed to creating sustainable value for global customers by focusing on technological innovation and customer-centric solutions. Equipped with advanced manufacturing and testing equipment—including automated brazing production lines, high-precision leak detection machines, thermal performance test benches, and vibration testing equipment—DENAISHI® has laid a solid foundation for producing high-quality heat exchange products. Backed by a strong technical force composed of senior engineers with over 15 years of industry experience and R&D specialists proficient in automotive thermal management systems, the company is capable of providing customers with tailored technical support, from pre-sales product consultation and model matching to in-sales installation guidance and after-sales problem-solving, ensuring that every specific issue encountered by customers is addressed promptly and effectively.A key technological advantage of DENAISHI® products lies in the specialized fin design: the fin of every brand product adopts a patented folding technology (utility model patent number: ZL201020595595.3) paired with high-quality materials. This innovative folding process enhances the structural stability of the fins, and the advanced brazing technology ensures firm bonding between the fins and the tubes, significantly improving the product’s lodging resistance—even under harsh working conditions such as long-term vibration or extreme temperature fluctuations, the fins remain intact and undamaged. Moreover, the folding design effectively increases the heat dissipation area by 35% compared to traditional flat fins, allowing for faster heat transfer and more efficient cooling performance, which is crucial for maintaining the stable operation of automotive engines.Among DENAISHI®’s diverse product lineup, the radiator for OPEL ASTRA G 2.2 TD 2172 Y22DTR 00- AT is a standout example of precise adaptation and superior performance. The OPEL ASTRA G 2.2 TD 2172 Y22DTR 00- AT, equipped with the reliable Y22DTR diesel engine, is widely used in European markets for its durability and fuel efficiency, but its engine is prone to generating significant heat during long-distance driving or high-load operation. The radiator for OPEL ASTRA G 2.2 TD 2172 Y22DTR 00- AT is specifically engineered to address this demand: leveraging DENAISHI®’s patented fin folding technology, it features optimized fin density and spacing that maximize heat dissipation area while minimizing air resistance. The radiator adopts a brazed structure that enhances corrosion resistance and leak-proof performance, ensuring compatibility with the OPEL ASTRA G 2.2 TD 2172 Y22DTR 00- AT’s cooling system and maintaining stable heat exchange efficiency even in humid or corrosive environments.Every radiator for OPEL ASTRA G 2.2 TD 2172 Y22DTR 00- AT undergoes a rigorous multi-stage quality inspection process before leaving the factory. It first passes raw material testing to ensure the aluminum alloy used for tubes and fins meets high-strength and thermal conductivity standards; then undergoes pressure resistance testing at 1.2MPa for 48 hours to eliminate potential leaks; followed by thermal cycle testing between -40℃ and 120℃ to verify performance stability under extreme temperatures; and finally passes vibration testing that simulates 100,000 kilometers of driving to ensure lodging resistance. This strict quality control system guarantees that the radiator for OPEL ASTRA G 2.2 TD 2172 Y22DTR 00- AT not only perfectly matches the original vehicle’s installation dimensions (no modifications required during replacement) but also exceeds the original equipment’s service life, reducing maintenance frequency and costs for vehicle owners.DENAISHI®’s commitment to quality and service has made its products popular among customers in Europe, Asia, Africa, and the Americas. The radiator for OPEL ASTRA G 2.2 TD 2172 Y22DTR 00- AT, in particular, has gained recognition from OPEL aftermarket distributors and repair shops for its reliable performance and reasonable price, becoming a preferred replacement part for OPEL ASTRA G owners. Beyond this model, DENAISHI®’s product range covers heat exchange systems for passenger cars, commercial vehicles, construction machinery, and other vehicle types, with customization capabilities to meet the unique needs of different customers. Adhering to the concept of "creating value through quality and service," DENAISHI® will continue to invest in technological innovation, optimize product performance, and provide global customers with more high-quality, cost-effective automotive heat exchange solutions, while maintaining its reputation as a trusted partner in the industry.

| MODELS: |

radiator for OPEL ASTRA G 2.2 TD 2172 Y22DTR 00- AT |

| CORE SIZE: |

600×368 |

| TANK SIZE: |

55/55×395 |

| CARTON: |

840*105*460 |

| PA: |

16/26 |

| OEM: |

1300196 |

| PRICE: | 32 USD |